Information

Misting Technology

By forcing water, by means of a high pressure pump, through our specially designed misting nozzles, we create a fog of ultra fine water droplets with an average size of less than 10 microns.

Cooling principle

Billions of tiny water droplets quickly absorb the energy (heat) present in the environment and evaporate, becoming water vapor (gas). The energy (heat) used to change the water to gas is eliminated from the environment, hence the air is cooled.

Evaporative cooling is responsible for the chill you feel when a breeze strikes your skin. The air evaporates the water on your skin, with your body heat providing the energy.

Humidification

Materials and process

Our systems are the most efficient solution to keep the right humidity levels of materials and of processes. Different levels of relative humidity provides adequate moisture content in all hygroscopic materials. Moisture content requirements vary greatly from one material to the next. The table here below shows typical hygroscopic materials which require specific RH levels to avoid moisture loss and materials deterioration and/or production problems.

Storage of Horticultural Crops

From the time of harvest and during all the period of their storage vegetables are subject to respiration and transpiration and this is on account of their reserve substances and water content. The more the intensity of these two natural processes are reduced, the longer sound storage time will be and the more losses will be reduced. For this reason, vegetables have to be handled and transported as soon as possible in the best storage conditions (optimal temperature and air relative humidity for the given species).

Click on the links below to find out more.

TIME version pumps

TIME version pumps are supplied with a digital timer that allows to control the amount of misting by programming a timer and setting the duration of ON and OFF spraying cycles.

This allows to save a great amount of water without loosing evaporative cooling performance.

During the OFF cycle the pump does not stop.

BPS by-pass system

The «BPS» system starts recycling the water to an external tank providing a 30 times more efficient pump cooling than a standard H.P. pump. Standard pumps, if switched ON/OFF (by cutting electrical power to the motor), overheat very quickly, the motor fan stops and water does not cool the pump: this causes dramatic seals and other mechanical parts damage after few weeks.TecnoCooling pumps equipped with BPS assure long lifetime and less maintenace, furthermore a cold running pump increases cooling effect and motor perfomance, saving energy.

Low noise motors

QES and LSP electric motor operates more quietly and efficiently, it is more reliable and offers better performance than its predecessor. Thanks to its low noise level, this motor is best suitable for applications where low noise and smooth operation play an important role. For the customer this means less energy consumption and thus lower costs. Moreover, less overheating allows better performances of motors in heavy duty applications.

Safety controls

SSC or «Safety System Control» shuts down the pump in the event of the pressure dropping below 40 bar preventing flooding caused by broken tubing (nozzles pipeline). It also prevents pump from dry running making it a reliable solution for safe 24H running systems.

VFD (VAR) pumps

'VAR' or 'VFD' functionality is a new integrated electronic management system. The new pump series 'VAR' would allow for any particular installations where it is needed to manage different areas independently.

The system checks working pressure in real time, and it keeps it constant. It also automatically adjusts the power and the pump flow to match the number of spraying nozzles.

It becomes possible to divide the plant in several areas that can be managed independently and automatically.

'VAR' system is also able to detect any faults in the misting system and when needed it automatically turns it off.

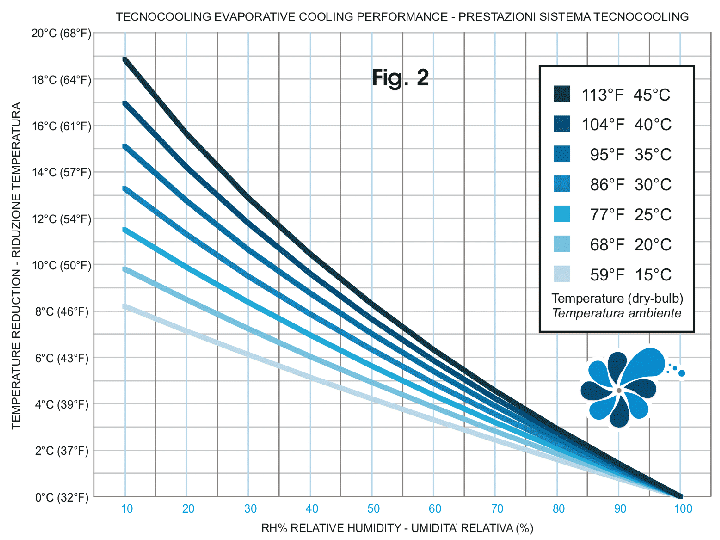

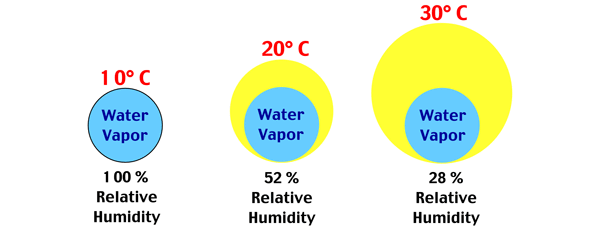

Relative humidity is the amount of moisture in the air compared to the amount of moisture the air could absorb at the same temperature, is a crucial factor in determining cooling potential. The lower the relative humidity, the more water can be vaporized, and the more heat can be removed.

Evaporative Cooling can be used effectively in most geographical locations. This is because when temperatures reach their peak during the day, humidity is normally at its lowest point.

A short explanation as to why dewpoint is a more accurate way to describe how humid it feels rather than relative humidity.